At IMTEX 2019, HCL will be showcasing CAMWorks 2019, the most advanced CAM software available, combining production-proven feature based CAM technology, automatic feature recognition, and rules based machining along with tolerance based machining to leverage MBD and PMI technology to automate Smart Manufacturing for CNC programming – paving the way to advanced digital manufacturing. HCL will be showcasing its proven technologies from booth A 114, Hall 6.

HCL has recently released CAMWorks Version 2019, which includes Additive Manufacturing, Tolerance-Based Machining (TBM) for turn and mill/turn parts, and improvements to Technology Database (TechDB).

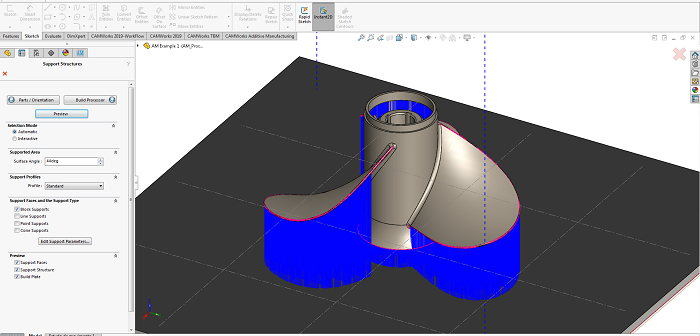

CAMWorks Additive Manufacturing, powered by Materialise® technology, introduces the first additive-subtractive solution available for SOLIDWORKS. With CAMWorks Additive Manufacturing, users can prepare models for their 3D metal printers inside SOLIDWORKS. The 3D printer model is then used as stock, and CAMWorks will generate the CNC subtractive machining operations and toolpaths needed to remove the build supports and machine other user-defined areas of the part, all inside of SOLIDWORKS. The design, additive and subtractive information are all stored within a single file, making it fully associative with the SOLIDWORKS model. Design changes made will subsequently be updated in the additive and subtractive programming.

CAMWorks 2019 also expands Tolerance-Based Machining (TBM) to turn and mill/turn parts, now with full integration inside CAMWorks. Tolerance-Based Machining provides technology to help users move their programming to Industry 4.0 procedures by recognizing and using Product and Manufacturing Information (PMI) – such as GD&T dimensions, notes and callouts – as well as Model Based Definition (MBD) information in the 3D model. With this information in the 3D model, users can eliminate the cost and manual tasks involved when using 2D drawings, and dramatically reduce the time needed to generate CNC programs for parts with close tolerances and surface finish requirements. CAMWorks TBM automatically selects the correct machining strategies to meet the tolerance requirements, and because it is fully associative with SOLIDWORKS, any tolerance changes made to the model will automatically be updated in the CNC programming.

CAMWorks 2019 also provides several improvements to TechDB – the CAMWorks Technology Database that captures programmers’ best practices and allows them save and reuse the information that defines how they prefer to machine parts. With TechDB, users can define their preferred tools, speeds and feeds, machining strategies and associative parameters for the CNC machines on their shop floor. In addition, the TechDB can be shared with other programmers and designers working together, saving programming time and standardizing output quality.

Among the additional enhancements released in CAMWorks 2019 are significant improvements to 5-axis swarf milling, multi-turret synchronization, production multi-turret turning, toolpath editing, collision checking, multi-axis chamfer milling and additional feature recognition functionality.