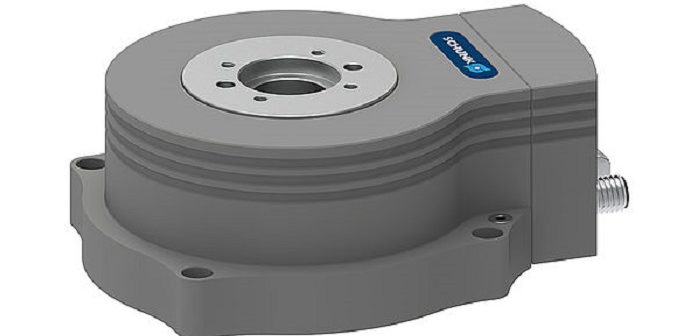

With the ERT rotary unit, SCHUNK is bringing a new generation of universally deployable, mechatronic rotary modules onto the market, which enable flexible, precise and dynamic rotary movements within compact spaces while remaining virtually wear-free and maintenance-free.

The flat, high-performance module is based on a permanently energized torque motor and is equipped with an absolute encoder. It also ensures immediate repeat accuracy of 0.01° with no need for a reference run, as well as quick response times, and high torques. A large-dimensioned center bore allows cables and hoses to be fed through and enables deployment of a camera.

Numerous variants and options

The rotary unit can be used for particularly flexible and compact plant concepts – as a rotary table for components, assembly groups and tools, and as a rotary module in gantry solutions, as a rotary indexing table or a high-precision positioning module. To ensure the maximum flexibility during control and regulation strategies, drive controllers from different manufacturers can be used so the module can be integrated seamlessly into existing system architectures. As a first step the versatile module will be launched onto the market at the start of 2020 in three sizes 12, 50 and 300 with rated torques of 1.2 Nm, 5 Nm and 30 Nm, outer diameters of 120 mm, 167 mm and 277 mm and maximum permissible mass moments of inertia of 0.0021kgm2, 0.2 kgm2 and 4.5 kgm2. The modules will be powered and activated via standard plugs (M12/M17). Optionally, they are also available with an electric brake. This is actuated over the controller and reliably maintains the position in downtime, even if an external force acts on it. The height also remains unchanged with an electric brake. Dust-resistant, splash-proof variant (IP54) will also be available. In a second configuration, optional rotary feed-throughs for hoseless or wireless feed-through of electrical signals, bus signals or fluids and other sizes are planned.